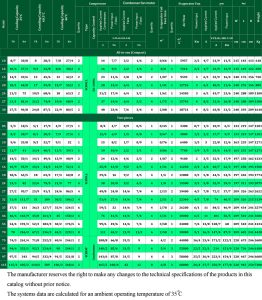

All-in-one (Compact) / Scroll type / APCC Series / 10-30 TR

Two-Pieces / Scroll type / APCA Series / 5 - 70 TR

Two-Pieces / Screw type / APSA Series / 75 - 115 TR

Rooftop packaged units (series APCC, APCA and APSA) consist of an air handling unit with DX (Direct Expansion) evaporator coil and a condensing unit including a compressor, condenser and refrigeration cycle equipment; it can use a heating coil for cold seasons as well. These air conditioning models are suitable for such places as shops, community halls, industrial/sport/exhibition complexes, and indoor amusement parks.

Features of rooftop packaged units (Series APCC, APCA and APSA):

Equipped with scroll and screw compressors (made by Copeland/Danfoss and

Bitzer/Hanbell Companies)

- Capable of being built either in one or in two pieces

- compatible with Industrial environments

- Using finned tube type evaporators

- Utilization of Centrifugal type evaporator fans

- External pressure drop of 100 Pa

- Axial condenser fans equipped with assembled fan motors

- casing with galvanized sheets covered with electrostatic paint

- the evaporator part is Fully double-walled with 25 mm polyurethane insulation and aluminum profiles

- Applicable under any weather conditions

- Fully bolt-and-nut assembling without any welding

Machine-installed conventional equipment:

- High and Low pressure mechanical control switches

- Compressor suction and liquid line valves for repair and maintenance

- Microprocessor controller with digital screen

- Mechanical temperature switch to protect the evaporator

- Water-flow differential pressure switch

- High and Low pressure transmitters

- Safety valve on the liquid line

- Compressor electronic protection module

- High and Low pressure indicator mechanical gauges for each separate circuit

- Compressor heater

- Connectability to the integrated BMS through the Modbus protocol

- G2 aluminum washable filter

- Phase control for input phases and phase symmetry

Custom-made possibilities:

- Rooftop Packaged unit with compressors able to store up to 100% of the refrigeration load in the machine unit structure

- Designability and producibility with inverter compressors

- Inverter installability to control the speed of condenser fans

- Designability with low-noise operation

- Designability with super low-noise operation

- heat exchangers producibility with copper pipes, copper fins and coated fins (e.g. Blue, Gold, etc.)

- Usability of different anti-corrosion coatings for condenser heat exchangers (e.g. Blygold, Heresite, Sakaphen, etc.)

- Usability of open-type screw compressors for specific applications

- Usability of 0-10 V or 4-20 mA analog inputs for set-point variations

- Controllability of all equipment through PLC with such brands as Siemens, Schneider Electric, etc.

- Usability of micro-channel condenser heat exchangers

- Operability during all four seasons

- Inter-connectability of multiple chillers manageable as a single unit and spare chillers and working hours management

- EC-type condenser fans

- Condenser centrifugal fans for special applications

- Usability of Plug and Backward-type evaporator fans

- Usability of an extra oil separator for each circuit

- F7 bag filter

- Digital inputs for upstream control

- Usability of thermostats in the upstream

- Designability and Installability of return fans

- Designability and producibility Hygienically

- Designability and producibility with chemical filters or such high-efficiency filters as HEPA, Activated Carbon, etc.

- Designability and producibility with steam heating heat exchangers, hot water or heating elements when heat is needed

- Usability of protective mechanical equipment including propulsion line silencers (mufflers), suction line accumulators and liquid line receivers

- Installability of controlling equipment to reduce energy consumption

- Installability of soft starters

- Usability of anti-freeze heater on the evaporator

- Installability of economizer using plate heat exchangers

- Installability of mechanical filters on suction and liquid lines

- Installability of such heat recovery heat exchangers as air-to-air or energy-recycling cycle

- Usability of protective grids on the machine lower levels and on the condenser coils

- Usability of electronic expansion valves in refrigeration circuits

- Installability of quick-connection hydraulic equipment

- Usability of water-seal chambers to protect condenser fans and coils in non-operational seasons

- Spring-type shock absorbers

- Possibility of equipping the system to different-dimension touch screens