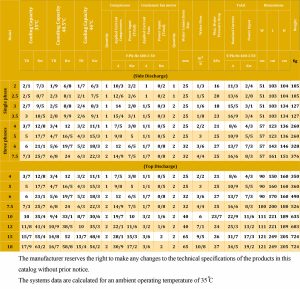

ALCM Series/ 02 – 18 TR

Packaged Air-cooled Mini chillers (ALCM series with scroll compressors) are designed and manufactured for use as independent building units cooling systems under different temperature conditions with desirable performance, high efficiency, low energy consumption, and fast and easy installation.

Compressors used in these chillers are quite popular because of their low part-depreciation, compact design, high efficiency compared to reciprocating compressors, very low noise, and long lifespans.

The Chillers (except single phase and 4 and 5 ton series) using two compressors causes optimal energy consumption in different modes.

Features of Air Cooled mini chillers (ALCM Series):

- Having Copeland or DANFOSS made closed scroll compressors

- Proper operation under all weather conditions

- Using plate type evaporators (For 2-6 tons refrigeration capacities)

- Using shell-and-tube type evaporators (For 7.5-18 tons refrigeration capacities)

- Using finned tube type condensers

- Equipped with axial-type assembled fan motors

- Having bodies of galvanized sheets with electrostatic coating

- Assembled fully with bolts & nuts without any welding

- Having two fully independent refrigeration cycles in series equipped with 2 compressors

- Having two evaporators in series equipped with 2 compressors

Conventional equipment installed on the machine:

- Equipped with compressor operating time-adjustment device

- High and Low pressure mechanical control switches

- Compressor suction and liquid line valves for repair and maintenance

- Phase control for input phases and phase symmetry

- Mechanical temperature switch to protect the evaporator (anti-freeze)

- Water-flow differential pressure switch

- Safety valve on the liquid line

- Compressor electronic protection module

- High and Low pressure indicator mechanical gauges for each separate circuit

- Compressor heater

- Connectability to the integrated BMS through the Modbus protocol

- With pump and expansion tank